A Biased View of Motorcycle Parts New Zealand Specialists

Table of ContentsThings about Motorcycle Parts New Zealand SpecialistsAn Unbiased View of Motorcycle Parts New Zealand SpecialistsTop Guidelines Of Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Fundamentals ExplainedThe Facts About Motorcycle Parts New Zealand Specialists RevealedSome Known Details About Motorcycle Parts New Zealand Specialists A Biased View of Motorcycle Parts New Zealand SpecialistsThe Motorcycle Parts New Zealand Specialists Diaries

Get to out to one of our professionals today.CNC machining modern technology is rapidly coming to be the centerpiece of several production procedures around the world as a direct outcome of its many advantages over various other methods. In addition, the industries that produce motorcycles have jumped on board with this trend. The most cutting-edge companies are now creating their engine components and wheels using machining strategies originally created for motorcycle parts.

On the various other hand, the results of industry are the main emphasis of this article. Let's obtain right into it. You may be questioning why we make use of. It is not hard to fathom the elements that brought about this outcome. Since we have your interest allow us clarify the reasoning behind this modern advancement in the bike manufacturing industry.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

In enhancement, you have total control over the look of the elements, also down to the minute information. Occasionally, motorcyclists might decide to spruce up their experience by installing aftermarket elements or changing the bike's makeover.

The Greatest Guide To Motorcycle Parts New Zealand Specialists

CNC machining might be made use of to make nearly all of a motorbike's metal and plastic elements. To continue, we'll talk about a number of machined parts for motorcycles.

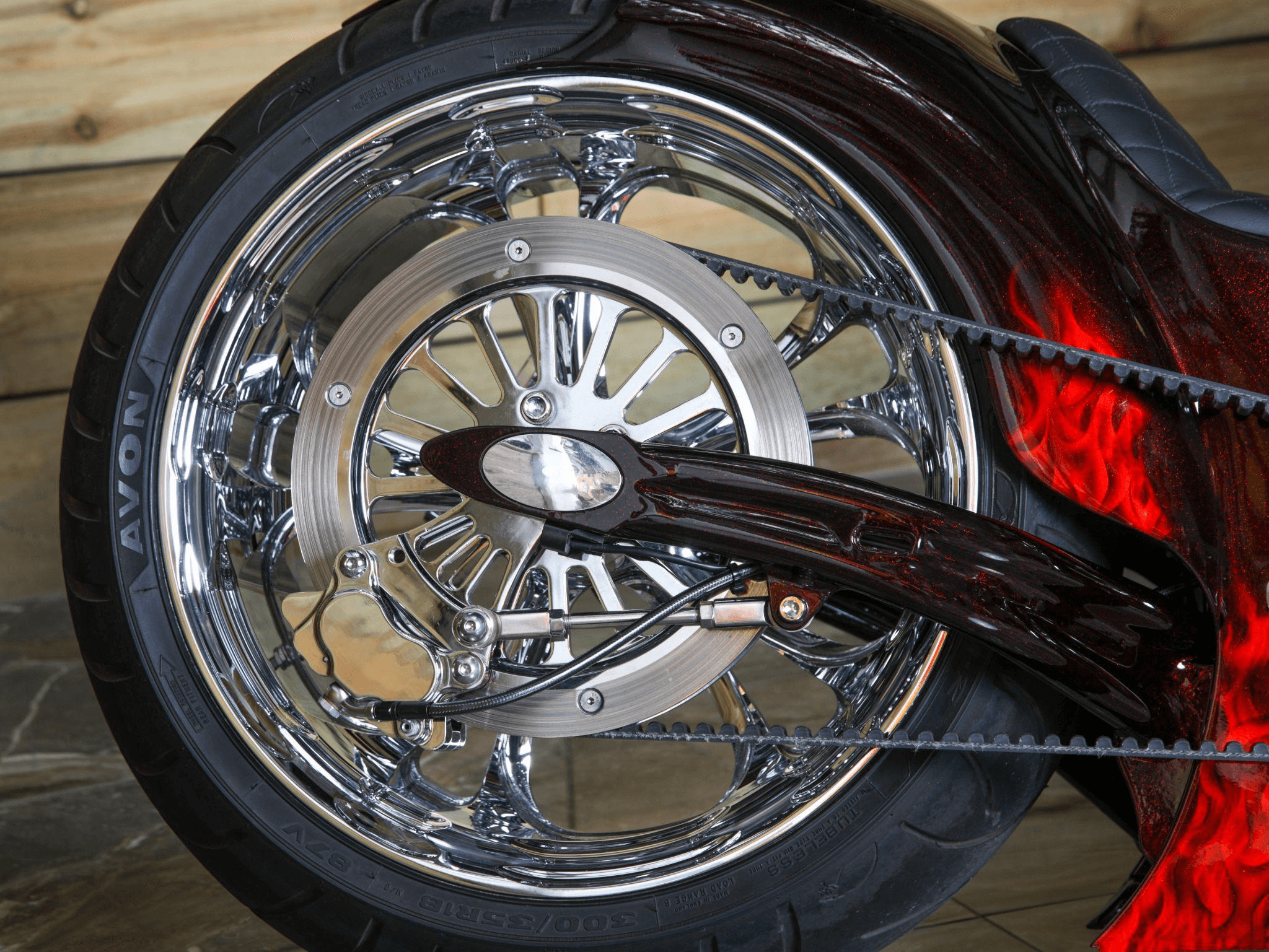

When customizing the wheels, the disks are where the focus should be. The majority of them are constructed of light weight aluminum. Light weight aluminum alloys are widely known for the impressive machining abilities that they possess. Milling procedures are used to obtain the wanted level of wheel personalization. Another aspect of the motorcycle that might be individualized is the tires.

The Facts About Motorcycle Parts New Zealand Specialists Revealed

When it concerns a lorry (or a motorbike), the most vital element is the engine. A number of individuals point to it as the "heart" of the auto. On the other hand, the camshaft, the cyndrical tube head, and the pistons tend to be detailed and require layouts with a high degree of precision.

Usage just top quality products, nonetheless, given that these lights are essential for the security of motorcyclists and various other vehicle drivers or web link individuals on the roadway, especially at night. Motorbike fronts lights have 3 main parts: the bulb, or light source, the lens, and the housing.

Milling procedures with a perfect coating would certainly cause the lenses having a reflective top quality that is similar to that of a mirror. The cover, on the other hand, is not composed of fragile materials; rather, it is constructed out of difficult polymers that can be machined into more intricate patterns.

Not known Factual Statements About Motorcycle Parts New Zealand Specialists

Motorcycle manufacturers commonly cast these components, yet only for the manufacturing of bespoke parts. Machining on 5 axes in today's globe is the means by which any kind of style form may be understood.

Select Runsom for your tailored motorcycle parts! We have the capacity to fabricate complex and elegant components making your motorcycle unparalleled.

Below are a couple of instances of metals commonly made use of in motorbike element machining. Light weight aluminum is the main material utilized by business specializing in creating customized motorbike elements to create most of these parts - Motorcycle Parts New Zealand Specialists.

Zinc describes an additional steel that is really light in weight and has wonderful machining qualities as a result of its high mechanical toughness. This product may be developed into practically any form and preserves its dimensions well. Even mission-critical parts that require a high degree of accuracy may take advantage of their usage.

How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

One more steel that sees hefty usage in the production of CNC-customized parts is magnesium. It is amongst the lightest metals that are now obtainable and has excellent machinability functions and strength compatible with its reduced weight. One of the disadvantages of magnesium is that its dirt might easily catch fire.

Their most common use in producing various motorcycle components is fasteners, such as screws and bolts. Their low susceptibility to oxidation and corrosion makes them perfect for this use.

Motorcycle Parts New Zealand Specialists - The Facts

It seems that CNC turning and crushing are the fundamental processes. Different methods exist, such have a peek here as boring. Let's investigate a number of these machining strategies detailed. The CNC transforming method is considered a subtractive production technique. In addition, it needs keeping bars of product, frequently plastic or metal, ready and after that turning a cutting tool to eliminate areas of the material as the product is turned.

These methods are equally crucial and produce parts with high precision and regular top quality. The procedures help enhance the overall quality of the machined motorcycle elements.

Things about Motorcycle Parts New Zealand Specialists